This article by Pole Star Global provides a comprehensive guide for understanding and managing supply chain disruptions caused by global challenges such as climate change, geopolitical conflicts, and trade shifts.

Readers will learn actionable strategies for building agile, resilient, and robust supply chains, improving visibility across all tiers, and leveraging digital technologies – such as predictive intelligence and real-time tracking – to anticipate and mitigate risks. It also demonstrates how Pole Star Global’s Maritime Intelligence solutions can enhance supply chain decision-making, compliance, and operational efficiency, preparing businesses to navigate future disruptions with confidence.

Key Statistics and Insights

The Global Impact of Disruption

- Between 2021 and 2023, supply chain disruptions accounted for approximately 60% of U.S. inflation.

- Seventy-two per cent of companies reported adverse operational impacts due to disruptions, yet only two per cent felt prepared to manage them.

- Demonstrating the true cost of supply chain disruption, during the COVID-19 pandemic, shipping prices peaked at US$30,000 per container, with 57% of businesses reporting “serious disruptions” and 72% reporting “negative impacts”.

How to Manage Supply Chain Disruption

- The proportion of companies maintaining inventory buffers dropped from 59% (2020) to 34% (2024), increasing exposure to supply shocks.

- To achieve robustness, experts recommend no more than 25% dependency on any single supplier, port, or route.

- Gartner Case Study: Stanley Black & Decker reduced disruption risk by focusing on the 20% of the supply chain generating 80% of revenue, balancing diversification with manageability (“surface area reduction” strategy).

- Reducing supply chain “surface area” (processes, sites, suppliers) can mitigate exposure without sacrificing resilience.

The Future Supply Chain

- By 2035, 45% of supply chains are expected to be largely autonomous, using robotics, drones, and driverless technology.

- Sixty-three per cent of companies have implemented, or plan to implement, AI and machine learning in their supply chains.

- Sixty-one per cent of businesses are investing in reskilling their workforce for digital transformation.

Pole Star Global’s Solutions Provide Supply Chain Professionals With Improved:

- Visibility: Near real-time vessel tracking, congestion heatmaps, and risk identification.

- Compliance: Sanctions screening, emissions tracking (ETS, FuelEU), and AIS integrity.

- Predictive Intelligence: Early disruption detection via vessel behaviour analysis.

- Voyage Optimisation: AI-driven and human-supported weather routing to reduce delays and supply chain “surface area”.

- Risk Detection: The PurpleTRAC system identifies high-risk entities (e.g. shadow fleets, sanctioned vessels) before official listings.

Climate change, conflicts in the Middle East, and the introduction of new tariffs in the United States are ongoing and emerging shifts that have, or may, cause significant supply chain disruption.

To manage these challenges, it’s essential you develop a plan that addresses these risks head-on. The goal should be to adopt a proactive approach that integrates risk tolerance into the core of your supply chain, to ensure competitiveness in the years ahead. This Pole Star Global article explores the latest research and insights to help guide you through this process. You are presented with key actions to prepare you for future supply chain challenges.

- The Challenge: The Global Impact of Supply Chain Disruption

- What Are Supply Chain Disruptions?

- Reducing Supply Chain Disruptions: Agility, Resiliency, and Visibility

- A New Approach to Mitigate Supply Chain Disruption

- The Future Supply Chain

- Measuring Your Readiness to Manage Supply Chain Disruption

How Can Pole Star Global Help You Mitigate Supply Chain Disruption?

This article provides a comprehensive overview of how Pole Star Global’s Maritime Intelligence software solutions can assist in mitigating supply chain disruptions. In summary, Pole Star Global equips supply chain stakeholders with:

- Visibility: Pole Star delivers near real-time vessel tracking, congestion heatmaps, and risk identification.

- Compliance: Pole Star’s solutions enable sanctions screening, environmental compliance (ETS, FuelEU), and AIS integrity.

- Predictive Intelligence and Voyage Optimisation: Pole Star’s predictive intelligence enables the early detection of disruptions through vessel behaviour analysis. Additionally, Podium’s voyage optimisation solutions provide 24/7 weather routing support, combining AI and expert human insights.

To learn more, jump to Transforming Supply Chains Digitally: Insights from Pole Star Global.

The Challenge: The Global Impact of Supply Chain Disruption

Supply chain disruptions have far-reaching effects, contributing significantly to economic instability. For example, between 2021 and 2023, these disruptions accounted for ~60% of inflation in the U.S. Plus, a survey conducted by Ernest and Young LLP revealed that 72% of companies experienced adverse operational impacts due to supply chain issues. Yet, only 2% felt prepared to address these challenges, highlighting a significant gap that underscores a widespread vulnerability.

What Are Supply Chain Disruptions?

Supply chain disruption refers to any interruption in the flow of goods, services, or materials within a supply chain. These disruptions are typically caused by external factors beyond an organisation’s control, such as:

- Natural events: Severe weather, earthquakes, or pandemics can halt production and disrupt transportation.

- Political issues: Trade restrictions or political instability can impact the availability of goods and resources.

- Economic challenges: Fluctuations in material prices or labor shortages can disrupt operations.

- Cyberattacks: As supply chains increasingly rely on digital systems, they become more vulnerable to cyber threats.

Such events can result in production delays, increased costs, and shortages of goods. Vulnerabilities, such as heavy reliance on a single supplier, a lack of transparency, and insufficient contingency planning, can further amplify the impact of these disruptions.

For instance, the ongoing conflict in the Red Sea has significantly undermined global trade. Houthi militants targeting vessels in the region have forced large ships to reroute around the southern tip of Africa, adding 14-25 days to their journeys. This longer route not only delays shipments but also drives up shipping costs that are ultimately passed on to consumers.

In another example, the COVID-19 pandemic created widespread bottlenecks across the global supply chain. Manufacturing slowdowns in China, labour shortages at ports, and shipping delays coincided with a surge in demand, which put immense pressure on container availability. As a result, shipping prices skyrocketed to $30,000 per container. In some cases, shipping companies and leasing firms found it more profitable to send empty containers back to China rather than deliver them to the U.S. for exports. As a result, 57% of businesses reported experiencing “serious disruptions,” and 72% reported “negative impacts”.

Evaluating the Extent of Disruption

Disruptions are typically classified based on two factors: the probability of occurrence and the severity of their impact.

- Low Risk: These disruptions have short-term effects and are usually resolved once the specific issues are addressed. Examples include logistical challenges or transportation delays.

- Medium Risk: These disruptions can impact production for weeks to months, often causing losses that must be reflected in the organisation’s quarterly financial reports.

- High Risk: High-severity disruptions have a major impact and long-lasting effects. An example is the COVID-19 pandemic, which had widespread economic consequences across multiple industries.

Reducing Supply Chain Disruptions: Agility, Resiliency, and Visibility

Global supply chains have faced extraordinary instability in recent years, from the COVID-19 pandemic to conflicts in the Middle East. These challenges can catch organisations unprepared. Many rely on traditional risk mitigation strategies focused on agility, resilience, and visibility, but is this enough?

Building Agile Systems to Mitigate Supply Chain Risks

An agile company can respond swiftly to unexpected changes or interruptions. With agility, businesses can quickly adjust operations – e.g., shifting production schedules, rerouting shipments, or sourcing from alternative suppliers.

Strategies for Building an Agile Supply Chain: The Role of Intermediate Inventory and Safety Stock

Despite the importance of industry buffers, a number of companies have begun to scale back these measures. That is, reliance on large inventory buffers has dropped from 59% during the COVID-19 pandemic, to 34% in 2024, partly due to cash or capacity constraints. This is concerning because maintaining buffer stock is essential for building agile operations.

While just-in-time inventory management has been a hallmark of efficient supply chains, having a buffer of essential materials or components on hand can help mitigate the effects of supply chain disruptions. Although holding inventory ties up capital and carries risks of obsolescence, the costs of disruption often outweigh the benefits of lean inventory processes.

Strategies for Building an Agile Supply Chain: Adopt the Process of Continuous Improvement

Continuous improvement is a core part of agile methodology. Thinking about supply chain agility, a recent study conducted by APQC recognised the growing adoption of agile methodologies such as Total Quality Management (TQM) and Plan-Do-Check-Act (PDCA) in supply chain management.

Specifically, 46% of survey participants believe that agility through continuous improvement is effective for their supply chain, and 25% rate it as ‘extremely effective’. Once more, 83% plan to dedicate more resources – be it personnel, technology, or funding – to continuous improvement.

Adopt continuous improvement methodologies to enhance your supply chain operations. Examples include the TQM and PDCA frameworks mentioned earlier, as well as other approaches such as Kaizen, Root Cause Analysis, and Business Process Reengineering (BPR).

Moving From Resilience to Supply Chain Robustness

Resilience is defined as ‘the capacity to recover quickly from difficulties.’ Under this definition, a resilient supply chain will recover effectively after an immediate disruption. However, recent perspectives highlight the growing importance of robustness, defined as ‘the quality of being strong, healthy, or unlikely to break or fail.’

While resilience enables supply chains to address short-term challenges, robustness goes a step further. A robust supply chain avoids the need for recovery from disruptions by preventing negative impacts from occurring in the first place. This proactive strength means a robust supply chain can withstand and address immediate and long-term challenges effectively.

Strategies for Building a Robust Supply Chain: Focus on Overdependencies

Building a robust supply chain focuses on reducing over-dependencies through diversification. For example, experts recommend that no more than 25% of a company’s products or services should rely on a single supplier, port, or route. This distributes risk and lowers the likelihood of a single point of failure.

Begin by analysing your supply chain operations from a geopolitical standpoint. Where are your supply chain partners located? What percentage of your supply chain partners are located in each area?For instance, consider the ‘China plus one’ approach. This strategy encourages companies to maintain operations in China while establishing production in another low-cost region. Examples include countries such as Vietnam, Thailand, and Mexico, which are common alternatives for labour-intensive manufacturing.

However, such diversification comes with challenges. Consider Southeast Asia as an example. While offering lower labour costs and geographic proximity to China, the region lacks large, efficient ports and logistics infrastructure. Furthermore, regional risks – such as the Asian financial crisis or the 2004 tsunami – highlight the need for even broader supply chain diversification.

China remains integral to global manufacturing due to its skilled workforce, extensive supplier networks, and advanced infrastructure. As such, the goal is not to eliminate reliance on China but to strike a balance where operations are diversified to mitigate risk while maintaining access to this vital market.

Strategies for Building a Robust Supply Chain: Decentralise operations

Decentralising operations involves establishing regional data centres and diversifying production and distribution networks. However, decentralisation demands improved visibility across the supply chain to empower teams with clear communication, data, and transparency. This enables them to act decisively and make informed decisions. The significance of supply chain visibility and strategies for enhancing it are discussed further below. (With this initiatives, be sure to strengthen cybersecurity measures to protect sensitive information and ensure operational continuity.)

Strategies for Building a Robust Supply Chain: Supplier Diversification

Supplier diversification is the third key step in building a robust supply chain. The concept is simple: avoid over-relying on a single supplier for critical goods or services. By establishing relationships with multiple suppliers, you ensure continuity in the face of disruptions. If one supplier encounters challenges, such as delays, price increases, or geopolitical issues, you will have alternative sources to turn to.

In addition, it’s essential to diversify your carrier options. Maintaining partnerships with multiple carriers and transportation modes – such as sea, air, and rail – provides flexibility, allowing you to quickly shift to alternative providers or routes when disruptions occur.

Strengthening Supply Chains with Greater Visibility

McKinsey & Company reports that, while many companies have made progress in understanding their direct suppliers, gaining visibility into lower-tier suppliers has become increasingly difficult. This is concerning because significant disruptions often begin deep within the network. As a result, when disruptions do occur, it typically takes companies two weeks to assess the situation and implement a response plan.

Yet, a lack of visibility not only delays response times, but also complicates compliance within an increasingly complex regulatory environment. Laws such as the European Union’s Corporate Sustainability Due Diligence Directive require companies to ensure that all supply chain inputs meet environmental and human rights standards. However, most companies aren’t prepared for these regulations. Only 9% report being compliant, while 30% acknowledge they are “significantly behind”. This emphasises the growing need for deeper supply chain transparency to mitigate both disruptions and regulatory risks.

Strategies to Increase Supply Chain Visibility: Supply Chain Mapping

Supply chain mapping is the practice of creating a visual representation of the movement of goods, information, and resources throughout a supply chain. It outlines the locations of suppliers, the path taken by key materials, along with timelines and costs, plus the interconnected relationships involved in production, storage, and distribution. The following steps will guide you in creating your own supply chain map.

Identify Key Stakeholders:

- Start by listing all your suppliers, wholesalers, distributors, and other entities that impact your supply chain. Then, document their suppliers and sub-distributors. “Keep things simple at the beginning. It helps to break down every step, so you can track how goods, information, and finances move through your system,” advises supply chain expert and founder of the Art of Tea, Steve Schwartz.

- Next, categorise each supplier based on risk levels, considering factors like the impact on revenue if a supplier fails, the recovery time for disrupted suppliers, and the availability of alternative sources.

Understand Stakeholder Relationships:

- Organise your stakeholders by function and their relationships to your business and to each other. This step reveals how each part of the chain interacts and where bottlenecks may occur.

Break Out Costs and Timelines:

- Detail how long it takes for materials to move between stakeholders and the costs associated with each step. For example, map the time and expense of shipping a component from Supplier A to Manufacturer B. Utilise specialist software to help you with this step. E.g., Pole Star Global’s Podium platform will optimise ship routes for accurate Estimated Time of Arrival predictions, allowing you to strategically map the timelines across your supply chain.

Visualise the Supply Chain:

- Create a visual representation of your supply chain using a linear timeline, a circular model, or a geographic map. Include delivery routes, costs, and contingency plans. Consider hiring a professional designer or using visualisation tools to support you in this step.

Strategies to Increase Supply Chain Visibility: Access Real-Time Data and Insights Across the Supply Chain

Once you’ve mapped your supply chain, you also need to ensure real-time end-to-end supply chain transparency. Opt for tools that leverage big data, intelligence systems, and connected ecosystems to drive visibility across the supply chain. This will enable:

- The quick identification of shortages, compliance risks, or other issues, allowing for timely adjustments.

- Enhanced consumer satisfaction and brand loyalty by ensuring product authenticity and traceability.

- Improved industry-wide practices that benefit the entire sector, not just the individual business.

The impact of technology and big data on improving supply chain visibility is further discussed below under The Future Supply Chain.

A New Approach to Mitigate Supply Chain Disruption

Given the increasing frequency of disruptions in recent years, relying solely on traditional supply chain management measures like agility, visibility, and resilience is no longer enough.

A recent study surveyed 70 Chief Financial and Commercial Officers (CFCOs) from large and mid-sized organisations, as well as 250 supply chain leaders worldwide, to explore how companies are addressing supply chain challenges. The results indicate that by actively reducing what is termed as a supply chain’s “surface area,” companies can minimise the risk of disruptions and transform potential threats into opportunities.

To explain further, a supply chain’s surface area is made up of two key factors: movement and footprint.

- Movement refers to the number of processes across the product lifecycle, including sales channels and touchpoints an order passes through.

- Footprint refers to the geographical spread of suppliers, factories, warehouses, and distribution centres, as well as the complexity of tier-two suppliers and material sources within the value chain. In this sense, this study turns traditional thinking on its head. That is, as mentioned above, the more diverse a company is, the more robust a company is thought to be. However, this diversification can increase supplier complexity. This will increase a supply chain’s footprint exposing the chain to greater risk. So, what can be done?

A case study is provided by Gartner Research to show how reducing a company’s supply chain surface area can help minimise the risk of disruptions.

How to Reduce a Supply Chain’s Surface Area: Case Study

Stanley Black & Decker, known for their tools and industrial doors, sought to reduce their exposure to disruption by diversifying their supply chain. However, this diversification expanded their supply chain surface area, increasing the company’s vulnerability.

In response, the company concentrated on the 20% of their supply chain that generated 80% of their revenue. By doing so, redundancy was built through diversification, but without significantly increasing the supply chain’s footprint. This approach demonstrates how traditional management processes can complement newer strategies. Stanley Black & Decker successfully struck a balance between risk mitigation and avoiding supply chain bloating.

To summarise, reducing a supply chain’s surface area, and therefore risk exposure, focuses on three levers:

- The number of processes (movement).

- The number of locations or sites (footprint).

- The number of suppliers (footprint).

It’s important to emphasise that any risk management approach – whether it’s reducing your supply chain’s surface area, creating more agile operations, building resilience (robustness), or improving visibility – should be implemented during the strategic planning phase. Traditionally, risk management has emphasised agility, resilience, and visibility during the execution phase of supply chain management. Shifting the focus to the planning phase allows for a more proactive approach, helping to minimise disruptions before they happen.

The Future Supply Chain

The future supply chain will prioritise intangible assets over traditional tangible ones, with data playing a central role. As such, digital technologies are indispensable for creating supply chains capable of withstanding significant disruptions.

Integrating Tangible and Intangible Assets

The supply chain industry is on the brink of a transformation. Once focused primarily on the physical movement of goods, the sector is now shifting towards the management of intangible assets. That is, the future supply chain will no longer be defined by trucks, ships, factories, and warehouses alone; instead, it will hinge on data, human knowledge, supplier agreements, and operational methodologies. These assets don’t show up on a balance sheet, but they can have a profound impact on a company’s success and ability to respond to disruption.

In the last decade, investments in intangible assets have soared, with human capital being one of the most significant areas to invest in. In the past, training and workforce development were viewed as costs to minimise. However, high-performing organisations are starting to recognise that investing in people can yield substantial returns. By enhancing the knowledge, skills, and decision-making abilities of their workforce, companies can improve efficiency, reduce costs, and better navigate the complexity of modern supply chains and an increasingly disruptive environment.

But it’s not just about the people. Knowledge systems also play a pivotal role. In many large organisations, knowledge is siloed and not shared across divisions. This lack of collaboration limits the ability to innovate and adapt quickly. To improve, organisations must create environments where knowledge flows freely, fostering collaboration both internally and with external partners. Having collaborative systems able to handle supply chain data and information is key and discussed further below.

The Role of Digital Technology

The future of supply chains is digital and autonomous. Research shows that by 2035, 45% of supply chains are expected to be largely autonomous, relying on technologies such as robots, drones, and driverless vehicles to automate logistics and planning. Plus, in 2022, 61% of businesses planned to reskill their workforce to adapt to emerging technological advancements.

The adoption of AI and machine learning is also expected to increase significantly, with 63% of companies already implementing these tools or planning to do so soon. This shift will enable smarter decision-making, process standardisation, enhanced visibility, and improved performance across the supply chain and client ecosystems.

To succeed in this digital transformation, businesses must shift from merely “doing digital” to “being digital.” This means utilising AI, big data, and analytics to make predictive decisions and enable the entire supply chain to adjust in real time to disruption and change.

Data quality challenges are a major bottleneck. It is recommended that companies adopt the 80/20 rule, focusing on implementing digital tools with available data and addressing gaps over time. To explain further, this means applying the Pareto Principle to data quality. That is:

- 80% of the benefits (such as improved efficiency, insights, or decision-making) can be achieved with 80% of the data.

- The remaining 20% of data might be incomplete or imperfect, but it doesn’t need to hold up progress.

Transforming Supply Chains Digitally: Insights from Pole Star Global

Pole Star Global understands the crucial role digitisation plays in managing supply chain disruptions. As such, Pole Star’s innovative technology acts as a centralised system to enhance visibility over the shipping portion of your supply chain. With advanced, persistent tracking technology, you gain accurate, near real-time data on a ship’s entire journey. This comprehensive visibility will help you improve supply chain disruption management in the following key ways.

1. Identify High-Risk Entities

Pole Star Global’s PurpleTRAC watchlists provide near real-time identification of high-risk entities within your supply chain to ensure regulatory compliance.

Plus, with Pole Star’s advanced tracking technology, you can proactively detect shadow fleet activity that could disrupt energy or commodity supply chains. You’ll receive timely alerts on suspicious behaviour with instant notifications. Suspicious entities are flagged and investigated even before they appear on official lists, ensuring you’re always one step ahead of potential threats.

Additionally, PurpleTRAC offers a wealth of detailed information, including ship owners and operators, P&I clubs, and a ship’s movement history, allowing you to thoroughly assess and understand each entity’s risk profile to make more informed decisions.

For instance, consider the recently sanctioned ship Sirius. The ownership structure of the sanctioned Barbados-flagged vessel is detailed in Pole Star Global’s PurpleTRAC.

PurpleTRAC identifies Sovcomflot as Sirius’s Group Beneficial Owner (see Figure 1). Vessels owned by Sovcomflot are subject to sanctions by the US, UK, and EU, well before the EU’s 15th sanctions package.

Figure 1: Ownership Structure of the EU-Sanctioned Vessel Sirius Revealed Sovcomflot as the Group Beneficial Owner Prior to the Ship’s Official Sanctioning

2. Voyage Optimisation and Predictive Intelligence

Through voyage optimisation, Pole Star Global empowers agile decision-making by providing alternative routes in response to changing conditions. Pole Star Global’s Podium platform gives you access to expert 24/7 weather routing services alongside Podium’s cutting-edge AI-based multi-objective voyage optimisation tool. This brings a unique and optimal blend of human expertise and watchkeeping with state-of-the-art technology and AI. The aim is to help you avoid potential supply chain disruptions caused by adverse weather. Podium’s predictive capabilities will recommend optimal routes to bypass weather-related delays and bottlenecks, keeping your supply chain running smoothly.

Plus, Podium‘s voyage optimisation capabilities will minimise time at sea, reducing your supply chain’s overall surface area by cutting unnecessary movement and boosting efficiency.

In terms of predictive intelligence, Pole Star leads the way in next-generation maritime analytics designed to detect disruptions early through advanced vessel behaviour analysis. This capability enables you to identify anomalies in vessel movements, such as route deviations, unusual loitering, unexpected port visits, or suspected AIS (Automatic Identification System) spoofing. Armed with these insights, you can anticipate potential risks, such as sanctions breaches or illegal activities, that could result in supply chain delays.

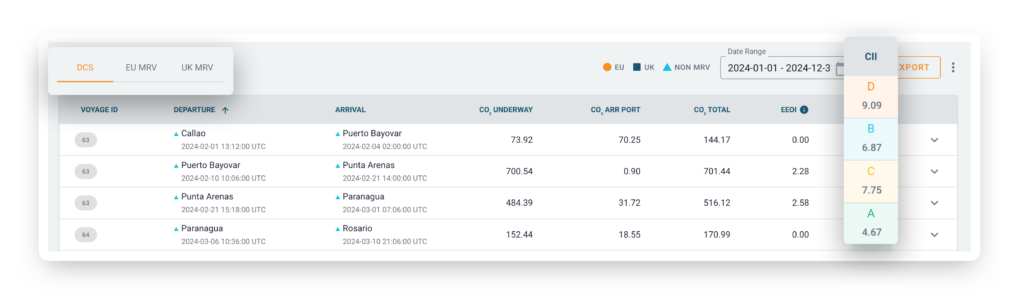

3. Compliance Assurance

Pole Star Global empowers maritime stakeholders to navigate the complexities of compliance with ease. For instance, ETS and FuelEU are supported to align shipping logistics with global and business-level environmental targets, ensuring future regulatory readiness.

Using advanced onboard emission tracking technology, you can measure the CO2 intensity per journey. Emission data is captured and reported in near real-time and stored in a centralised platform. This means you can easily access, review, and analyse the information you need to ensure ETS readiness.

Pole Star Global also supports AIS integrity by providing persistent tracking technology to monitor and verify vessel transmissions, ensuring compliance with sanctions and legal requirements. Pole Star’s unparalleled tracking capabilities detect anomalies in AIS signals, such as spoofing attempts, signal gaps, and other inconsistencies in a vessel’s reported position. To learn more, download our report: Unveiling the Dark Fleet and the Latest in AIS Spoofing (Four-Part Series).

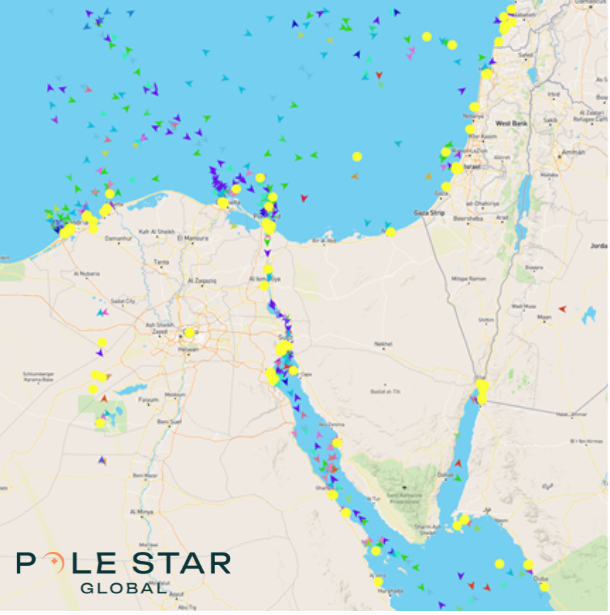

4. Improve Supply Chain Visibility

Pole Star’s real-time vessel tracking, congestion heatmaps, and risk identification give full visibility into your supply chain. As previously mentioned, this visibility is crucial for minimising disruptions. It allows you to quickly address potential issues before they affect your operations.

For instance, as disruptions in the Red Sea persist, Pole Star Global can monitor vessel traffic through key chokepoints such as the Suez Canal. Figure 2 illustrates the traffic flow through the Suez Canal, with coloured arrows representing over 50 different ship types, including General Cargo Ships, Bulk Carriers, and Crude Oil Tankers. Yellow dots indicate ships that are stopped, anchored, or moored. By monitoring traffic flow as such, you can make informed decisions on rerouting shipments, using Pole Star’s Podium platform to select the most optimal alternative.

Figure 2: Vessel Traffic Through The Suez Canal During the Red Sea Crisis

Measuring Your Readiness to Manage Supply Chain Disruption

To conclude, the key insights from this article have been used to develop the assessment criteria below. Complete the questions to assess your supply chain’s readiness to handle disruption. Use your answers to identify priority areas for improvement.

Do you have a plan to acquire the digital talent and services needed for supply chain operations?

Can you assess the risk status of tier-two and tier-three suppliers?

Do you have an effective early-warning system for supply chain risks?

Are AI tools used in supply planning to evaluate risk scenarios?

Does your board fully understand supply chain risks, and is it willing to invest in mitigation?

Have you diversified the most profitable segment of your supply chain – the portion that generates 80% of your revenue – in terms of suppliers, geopolitical locations, and carrier options?

Have you decentralised your operations, but centralised data management?

Have you established continuous improvement processes within your supply chain?

Do you have buffer stock (inventory) in place to manage potential disruptions?

Have you streamlined the processes throughout your product lifecycle?

These questions should serve as a benchmark to identify gaps in your supply chain operations and help you develop a strategy for closing them. Understanding where your supply chain stands today is the first step toward building future-ready operations.

When it comes to shipping, Pole Star Global is here to help you unlock the full potential of your supply chain through greater visibility and enhanced decision-making capabilities.

Contact a member of our team today to discover how Pole Star Global can provide unparalleled visibility into the blind spots of your supply chain, helping you stay ahead of disruptions and optimise your operations for the future.