Voyage Informatics is the application of data to improve the safety, efficiency and sustainability of marine transportation.

Podium5 is capable of processing and visualising billions of data points every month and seamlessly correlates manual voyage reports, weather and environmental data, multi-source positional data and high-frequency sensor data.

It is now possible to measure and manage performance in new ways using combinations of established and innovative technologies, moving beyond traditional manual reports with a greater scope, better frequency and lower latency of data points. The Podium5 Connected Community exists to help ship operators explore what is possible within the platform and advance their digital journeys. There is no better way to illustrate this than to give some real life examples.

Sensor and system networks

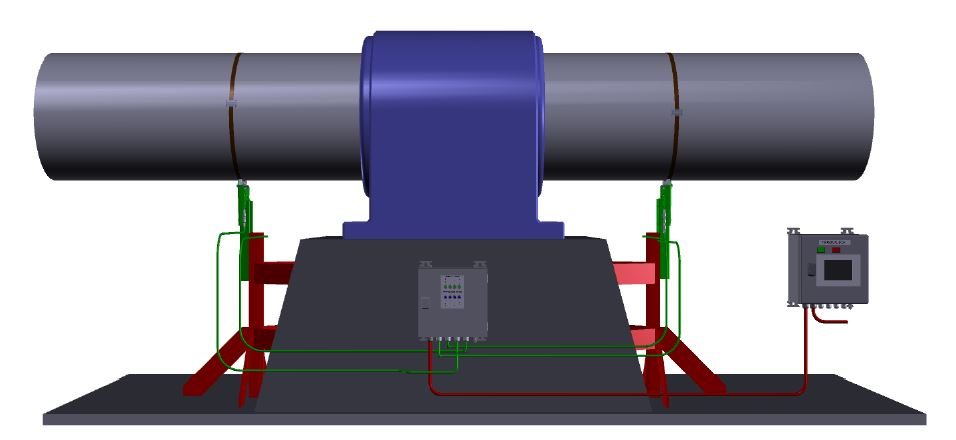

TX Marine specialises in a range of machinery measurement tools which are increasingly essential to better manage performance, increase efficiency and reduce emissions. Some of the major wins are relatively easy to achieve with sensors such as shaft torque meters.

Shaft power is an essential input (KPI) to Ship Performance Monitoring Systems for determining ship efficiency. Actual shaft power measurements provide an accurate reference point to assist with the assessment of:

- Engine Performance Monitoring

- Hull Condition

- Propeller Condition

- Specific Fuel Consumption

- Operational Efficiency Planning

- Ship Condition Changes

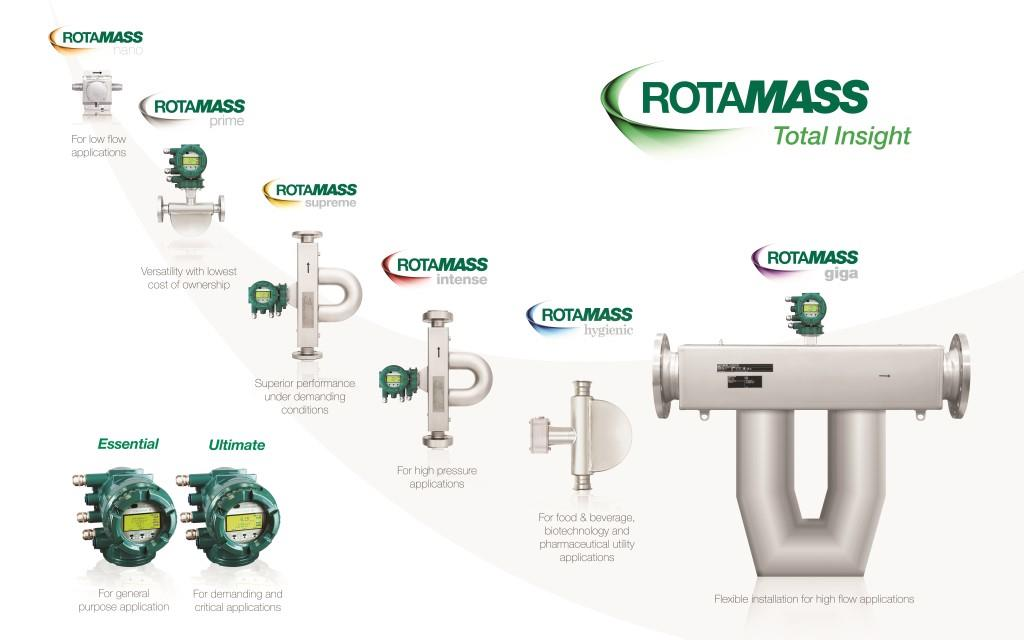

With an ever increasing focus on verifiable fuel consumption and emissions operators are also moving beyond bob tapes and sounding rods and installing more precise measuring devices such as flowmeters.

For example, the Rotamass TI series is a Coriolis mass flowmeter providing very high accuracy for measuring liquids and gases, especially for zero stability the series is one of the best in the industry.

From the direct mass flow, density, temperature measurements, with the Rotamass TI you can calculate:

- Volume flow at operating or reference conditions

- Density and Temperature Measurement

- Viscosity

Increasing the number of sensors is only part of the solution. Data can still be siloed, without context and inaccuracies may be difficult to detect as a result. It can also be the case data is communicated infrequently, delaying analysis, insight and action.

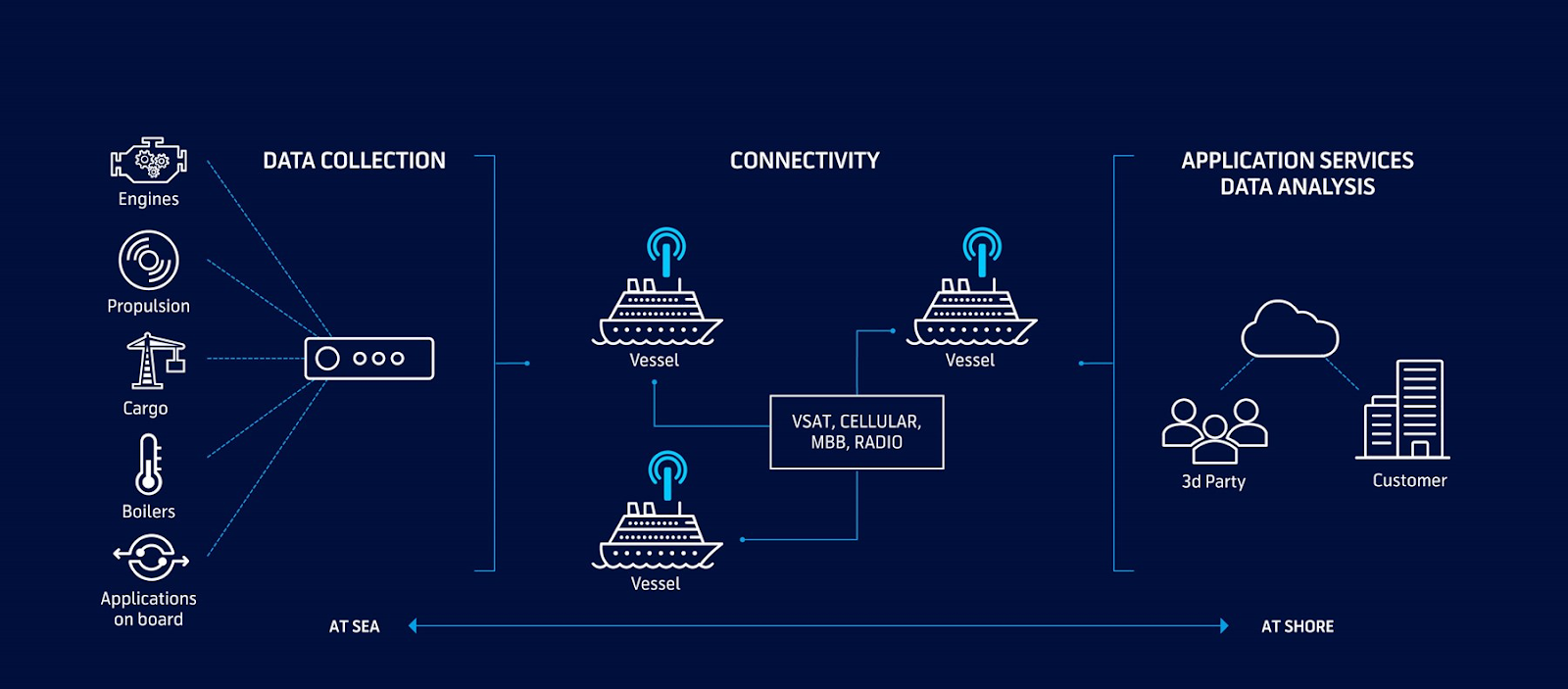

Communication, API and security

The Connected Community can also offer solutions in this area. In this case Telenor Maritime and its WaveAccess Collect end-to-end data service enables ship operators to collect, standardise and share operational data.

WaveAccess Collect can be integrated to any interface on-board and data can be shared to any application through pre-defined API according to data owner requests. Data can be transmitted over VSat, Mobile Broadband or a novel HF solution. Both interfaces, hardware and software are in accordance with high security standards. IMO standardised output, ISO-19848 ISO-19847 and ISO 27001 as company security standards.

Podium5 Visualisation and Insight

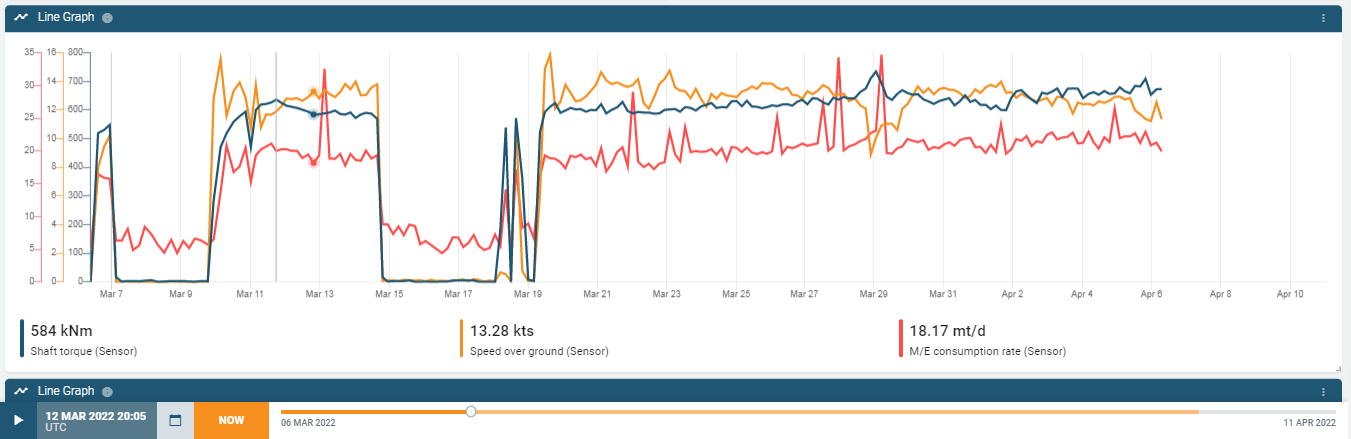

Podium5 receives the data via API and the separate data points can then be configured to provide a contextualised view of performance and analysed.

In the diagram below we have compared the streaming feeds from a shaft torque meter with the instantaneous fuel consumption values and speed over the ground. In isolation these data points do not indicate much, but combined they provide a fuller picture of performance and easier anomaly detection. Additional data fields such as wind, wave,swell and current provide environmental factors to assist with interpreting technical performance.

With a better understanding of applicable ranges in values a rules engine permits the user to set operating parameters and program alerts for non-conforming conditions.

Conclusion

There are no technical barriers to the development of improved systems of onboard data collection, transmission, analysis and action. The Connected Community and Podium5 can provide an end to end solution making the most of manual voyage reports, weather and environmental data, multi-source positional inputs, high-frequency sensor data and apply them to improving the safety, efficiency and sustainability of operations.

Stay connected and safe.